Sustainable Additive Manufacturing

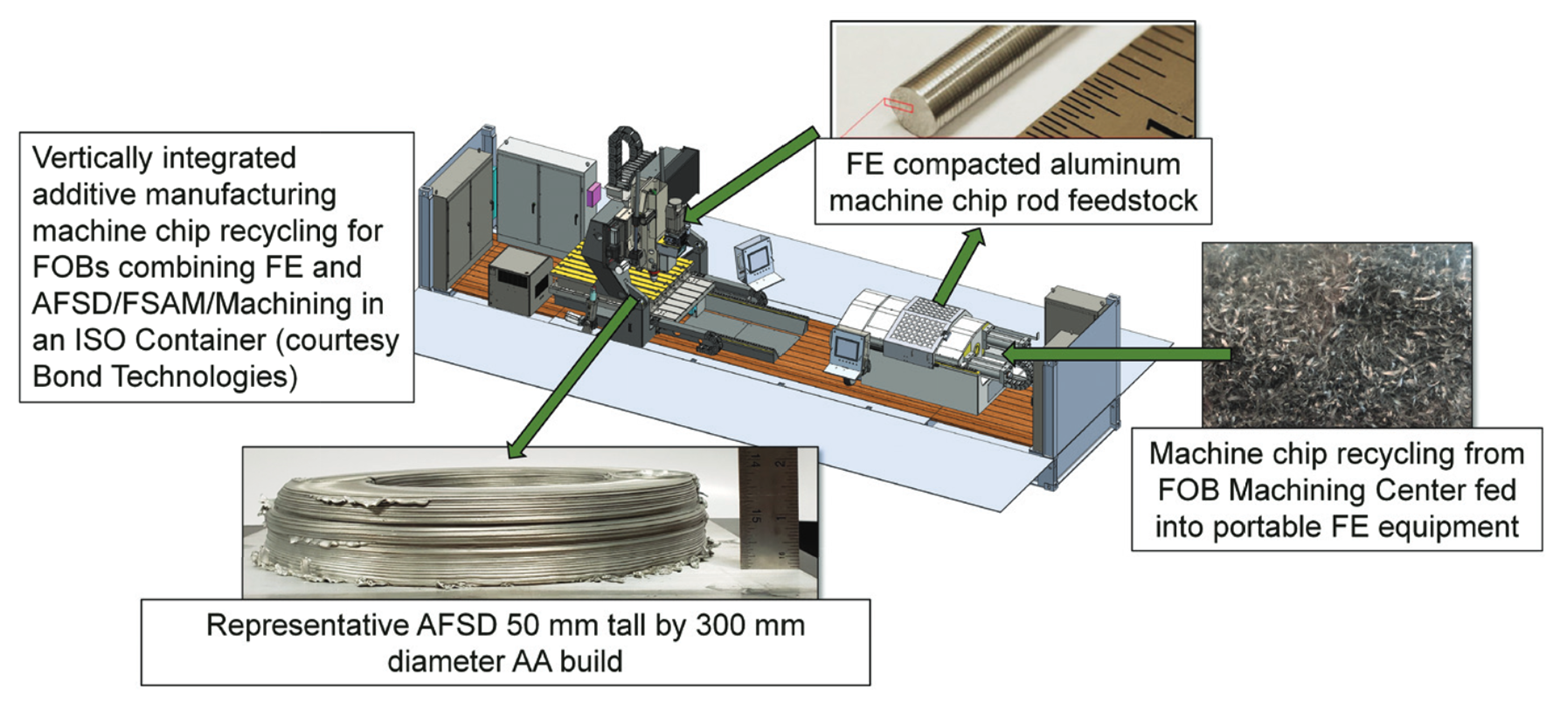

From repair of damaged components to fabrication of components from waste streams such as machine chips, the PONI Center has used the additive friction stir deposition (AFS-D) process to repair aerospace-grade aluminum and airfield matting. AFS-D is an open-air, solid-state additive manufacturing process that can use solid rods, machine chips, or strips of metal as feedstock and deposit near-net shape components quickly with low-power consumption. As AFS-D can use a variety of materials as feedstock and can deposit dissimilar material, AFS-D is well-suited for sustainable additive manufacturing at the point of need.